Clean heating – innovative & modern

The idea of a simple and clean heating system was born 10 years ago. Since then, KWB experts have been continuously working on improving the KWB heating systems even further. Particularly the combustion was an important innovation step. Our motto: Even fewer emissions and fine dust! This is what the revolutionised cleanEfficiency 2.0 label stands for.

The cleanEfficiency 2.0 technology is characterised by:

The emitted fine dust was reduced to under 2.5 mg

with the innovative burner concept cleanEfficiency 2.0 technology

thanks to maximum fuel utilization and a consistently high efficiency

of design and control elements

Even fewer emissions and fine dust

The revolution: After many months of research, KWB was able to reduce the emitted fine dust to under 2.5 mg. Thanks to this technology, KWB heating systems not only comply with highest European environmental standards, they even go a step further. Moreover, the limit values of the EU Ecodesign Directive are met and even undercut in terms of emission values, efficiency and energy consumption.

The core of our innovation

KWB heating systems are even cleaner thanks to the newly designed, innovative burner concept based on the cleanEfficiency 2.0 technology. Three different burners are used in KWB’s premium heating systems. The goal of all burner systems is a stress-free and undisturbed combustion. The idea is to move the fuel as little as possible to reduce emissions as far as possible.

Clean heating with the KWB underfeed burner

Pellet operation: The generously sized burner plate ensures a stable firebed and allows the pellets to fully burn out. Falling ash is avoided with the automatic ash removal from the burner plate. The cyclone technology pushes the dust particles to the outside and drops them into the ash box. The creation of fine dust in the combustion chamber is drastically reduced with the cleanEfficiency 2.0 technology. Same combustion system, fewer emissions. By increasing the firebed height, the pellets are burned more efficiently. The fine dust particles hardly evaporate, they bind to the ash and are subsequently removed.

KWB Crawler Burner for different fuel qualities

The robust KWB Crawler Burner, which is used in pellet systems or wood chip systems, is built according to industrial standards and functions like a type of conveyor belt for fuel. The movable grate has no trouble handling different fuel qualities. Here also the pellets or wood chips are burned particularly cleanly because the firebed remains undisturbed and no dust particle are kicked up. In this process, it is the Crawler Burner that moves, but not the fuel itself. The combustion process was improved to heat with the lowest emissions. In addition, the optional exhaust gas recirculation takes a portion of the cooled down exhaust that is produced during combustion and recirculates it to the combustion chamber. This cools the firebed at the grate thereby minimizing the fine dust production.

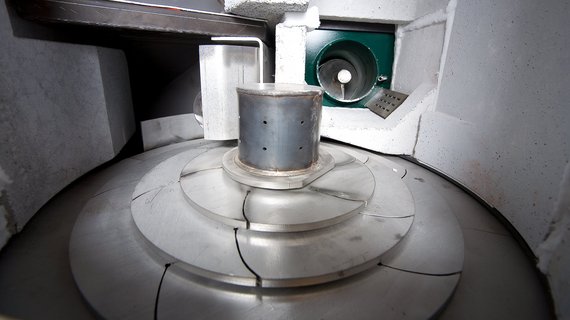

KWB revolving grate burner with cyclone combustion chamber

The KWB revolving grate burner with cyclone combustion chamber is responsible for a particularly quiet and undisturbed combustion in pellet systems and wood chip operation in a large output range.The revolving grate combustion system is a unique system in which the fuel is pushed sideways into the pre-combustion chamber and conveyed onto a revolving grate. The fuel is transported through the combustion chamber by means of grate rotation before a special grate cleaning system handles ash removal. Thanks to the cleanEfficiency 2.0 technology, the revolving grate principle used is equipped with a staged combustion air supply and ensures maximum fuel utilization and a permanently high degree of efficiency and low emissions thanks to the cyclone combustion chamber.

Easy operation with KWB control technology

The KWB Comfort 4 control concept ensures optimum combustion conditions, lowest emissions and maximum economic efficiency. The intelligent control logic quickly reacts to changes in the combustion process which is, for example, caused by fluctuating fuel qualities.